| What's Hot! | Products/ Tools | EFI Tuning | Basic Tuning | Advanced Tuning | Chassis Tuning | Advertise with us |

Understanding Camshafts

Camshaft Basics From the February, 2009 issue of Chevy High Performance By Bob Mehlhoff

It's Greek jargon, or street parlance to the rest of the world, but it often defines us. Whether we're talking about axle ratios, compression, carburetor size, timing, or e.t.'s, our hot-rod language sets us apart. And perhaps nothing else is discussed as emotionally as camshafts. Lift, duration, lobe center, overlap, and much more confer just how the camshaft will or will not alter an (often theoretical) engine's performance personality.

In scientific terms, it's all about the area under the curve. Just like that calculus class you wished you didn't have to take (or avoided altogether), the camshaft in your engine is largely based on the same mathematical rules. To allow more airflow into your engine, a camshaft is designed with a profile (or curve) that provides a specific amount lift to the valve.

So in this issue, we're going to do some heavy bench racing and delve into camshaft basics. The better we understand how each of these terms affects an engine, the better armed we are to choose the best camshaft. So hang on, cam speak is coming up.

Lift

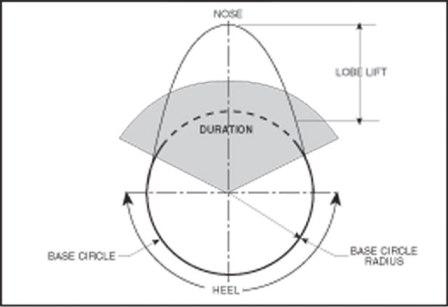

One of the camshaft's most fundamental tasks is to transform its rotating motion into linear motion or lift. This is accomplished on a typical Chevy V-8 with 16 lobes (an intake and an exhaust)--all of them ground to an eccentric shape called a lobe to allow each lifter to raise and fall above a base circle. Just how far (mathematically) each lobe raises the lifter is called the lobe lift. The lift that is typically referred to in a camshaft catalog is the valve, or gross lift, and is achieved by multiplying the lobe lift by the rocker arm ratio. For most small-blocks, the standard rocker ratio is 1.5:1, so, by multiplying a theoretical lobe lift of 0.370-inch x 1.5 rocker arm ratio, we achieve a valve lift of 0.555-inch lift (0.370 x 1.5 = 0.555).

By replacing the standard rocker arm ratios with a higher-ratio rocker arm, you can add valve lift and some duration. If we use the camshaft with the 0.370-inch lobe lift and match it to a rocker arm ratio of 1.7:1, we realize a gross lift of 0.629 inches. Though these two gross lift examples are close to the upper end of a very high-performance small-block Chevy with a flat-tappet camshaft, the mathematical theory is the same for all engines.

Duration

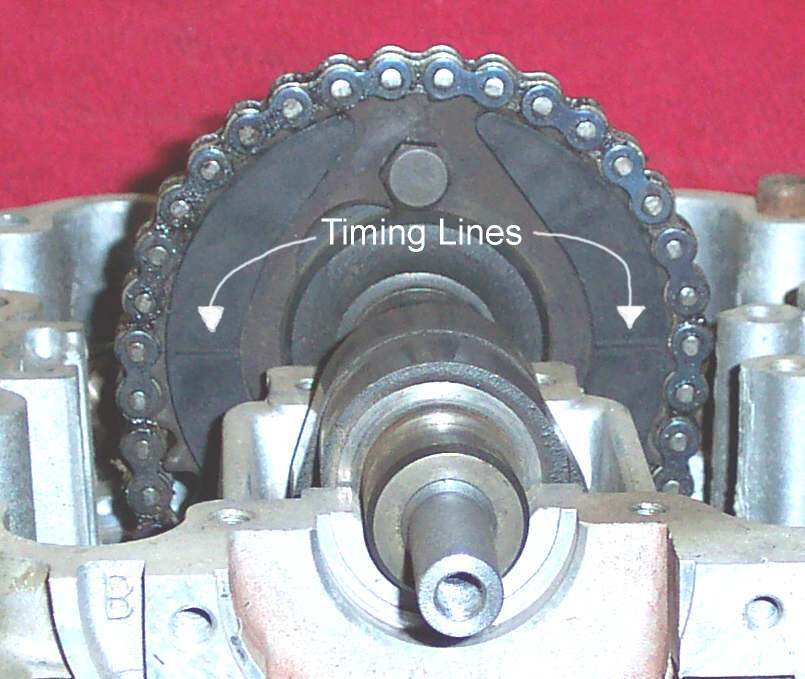

Camshaft duration is the amount of crankshaft rotation that occurs as the cam lobe moves the lifter off of the base circle; it is measured in crankshaft degrees to make it easier to degree (check) the cam to make sure it is positioned properly in the engine. Determining the specific point that the lobe begins to move, the lifter off of the base circle (upwards) can be difficult--so most camshaft companies use a standardized checking point to reference lift. Consequently, the camshaft industry has established a common duration checking point of 0.050-inch lift. As an example, Howards Cams' small-block hydraulic flat-tappet Max Torque camshaft (PN 112021) Chevy measures 222/232-degree duration on the intake and exhaust, respectively at 0.050-inch lobe lift, whereas the advertised duration is 288/302 degrees.

Generally, added duration is helpful in high-rpm engines, but not typically in low-rpm engines. This is because the added time that the valves are open in high-rpm engines allows the airflow additional time to enter or exit the cylinder. But at lower rpms, the added duration opens the valves too long in relation to the piston's position in the cylinder, and the pumping pressure is lost.

It's also important to discuss the opening and closing points of the valves. The intake opening (IO) typically occurs before top-dead center (BTDC) and intake closing (IC) occurs after bottom dead center (ABDC). Exhaust opening (EO) happens before bottom-dead center (BBDC) and exhaust closing (EC) after top-dead center (ATDC). These points can be checked by degreeing the cam in the engine by degreeing or simply referencing from the information on the cam card supplied with each new camshaft.

These values can therefore be verified when the cam is installed and degreed. If you're not sure of the duration of your camshaft but have determined the intake and exhaust closing points, you discover the duration by adding the opening and closing point values to 180 degrees. For example: if the intake valve open value is at 0.050-inch lift of 2 degrees and has an intake closing value of 40 degrees, we simply add both amounts to 180 (2 + 40 + 180 + 222) and we have 222 degrees of duration at 0.050-inch lift. This works just as well for the ex-haust side.

Lifters

Camshaft lifters, also called followers, are offered in hydraulic flat-tappet, solid flat-tappet, hydraulic roller, and solid roller designs. The hydraulic flat-tappet is the most commonly used largely because it offers the benefits of quiet operation and is available with most all camshaft profiles designed for either pure stock operation to very high-performance applications operating to about 6,500 rpm. Once a good hydraulic lifter has been adjusted properly, it generally remains adjusted because of a valve-controlled plunger inside the lifter that maintains a preload from engine oil pressure.

Mechanical (or solid) lifters are generally used for applications where very high rpms are expected--typically to 8,000 rpm or more. Although a solid lifter has an oil-fed orifice, it is still a mechanical lifter. To allow for expansion that occurs from varying engine temperatures, mechanical lifters maintain a certain valve lash clearance at the rocker arm and require periodic valve adjustments.

Roller lifters employ a small wheel at the bottom of the lifter that allows it to negotiate a very aggressive lobe design with more lift at a given duration and reduced friction. Roller cams are offered in both hydraulic and mechanical designs in a variety of performance profiles and are typically more expensive to install than the flat-tappet varieties.

Single and Dual-Pattern Camshafts

If you've ever looked at a cam card (furnished with each new camshaft), you've probably noticed that some cams have the same specs for both the intake and exhaust (single pattern), while others differ (dual pattern). A dual-pattern camshaft generally offers more exhaust duration to improve the flow of an otherwise marginal cylinder-head exhaust port.

Intake Centerline

The cam's centerline specification is used to determine the position of the lobes on both the cam and as installed in the engine. Most cam companies include an intake centerline number, which is the position of the intake lobe centerline (in crankshaft degrees) relative to top dead center on piston number one.

This can be altered by degreeing the cam after it's been installed in the engine. Moving the camshaft from its installed position affects all four opening and closing points; generally, the most important is intake closing. So by advancing the cam, the intake valve closes sooner. While this improves low-speed torque, it compromises top-end power.

Separation

Lobe separation angle (LSA) refers to the distance or spacing between the intake and exhaust lobe centerlines. This value is expressed in camshaft degrees, not crankshaft degrees. This is an important dimension because it establishes the amount of overlap between the intake and exhaust. Lobe separation angle (unlike the intake centerline), can only be determined when the cam is ground.

Conclusion

Choosing the best camshaft depends on vast criteria. If you use your car for daily transportation, you'll want to consider a camshaft with shorter duration and relative lift. Most of the cam companies offer copious assistance to match the best cam with the type of driving or racing you do. If you're looking for something wild, remember to match the rest of your engine and vehicle to your cam choice. Transmission type, vehicle weight, stall speed, compression, cylinder heads, and much more only begin the list. In this section, we've only touched on the fundamentals of camshafts. If you'd like to learn more, visit the some of the cam manufacturer's Web sites (listed in the source box). They hold a wealth of camshaft knowledge that is ever-evolving, and the tech sections of these Web sites are packed with information. Understanding the basics of camshafts may be difficult at first, but after reviewing the information, you'll find that you've learned quite a lot. The knowledge that you gain will surely help you choose the best cam for your particular engine.

***Remember*** to check for other relevant information in the columns and article tables.

ATTENTION READER:

If you enjoyed the information and article you just read be sure to check out our newly released book with even more exciting photo's and information:How to Turbocharge and Tune your Engine

Want to know more about your particular Make and Model vehicle? All of these vehicles are covered in the tech, maintenance and repair articles found above. Enginebasics is the wiki or wikipedia of car part, repair, how to and tuning information. Let us be the class 101 for your automotive learning.

| Ford | General Motors GM | Pontiac | Jaguar | Land Rover | Nissan |

| Toyota | Honda | Lexus | Acura | Lotus | Scion |

| Infinity | BMW | Mercedes | Mitsubishi | Ferrari | Maserati |

| Lamborghini | Volks Wagen VW | Saab | Audi | Hyundai | Kia |

| Subaru | Mazda | Chevy | Volvo | Caddilac | Dodge |

| Chrylser | Daewoo | Porsche | Mercury | Freightliner | MG |

Individual Models

| Ford Mustang | Mitsubishi Eclipse | Mitsubishi Evo | Subaru WRX / STI | Dodge Viper | Chevrolet Corvette |

| Nissan Skyline | Honda S2000 | Nissan 350z | Toyota Supra | Chevy Camaro | Lotus Elise Exige |

| Honda Civic | VW Golf | Dodge SRT-4 | Eagle Talon | Acura Integra | BMW M3 |

| Nissan 240sx | Porsche 911 | Acura NSX | Honda Accord | Toyota Camry | Toyota MR2 |

| VW R32 | Dodge Truck | Mazda Rx7 | VW Jetta | Sand Buggy | Nissan Sentra |

For the latest Automotive news and stories visit the websites below |

Our feature Build: An AWD V6 Civic